|

Industrial Water Process

Page 3 / 5 |

|

|

|

|

|

| |

|

|

Treatment of washwater from a

blast furnace's smokes |

| |

|

| |

Capacity : 2x450 m³/h |

| |

|

| |

Settling :

specific clarifier with bottom sludge scraper |

|

|

| |

|

|

|

|

|

Water treatment in a

galvanization factory |

| |

|

| |

Flow rate : 215 m³/h |

| |

|

| |

Carbonate removal

HYDROGYR TD |

| |

|

| |

Filtration through "pressure" horizontals filters. |

| |

|

|

|

Water treatment on secondary lines of

continuous castings |

| |

|

| |

Capacity of the treatment : 760 m³/h |

| |

Filtration through several "pressure" filters. |

| |

|

|

|

| |

|

|

Filtration in derivation

on a cooling line of tinning |

| |

|

| |

Capacity : 30 m³/h |

| |

|

| |

|

|

|

|

| |

|

|

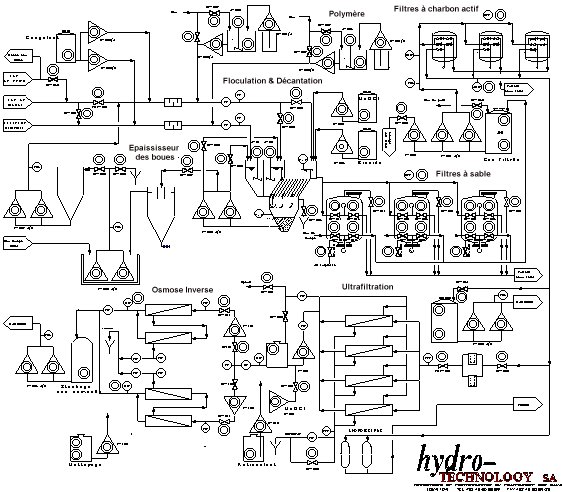

Process water for a

production line in a

glass industry. |

| |

|

| |

Preliminary treatments before filtration on porous

membranes - flow rate : 40 m³/h

|

| |

| * |

coagulation |

| * |

flocculation |

| * |

bacterial removal |

| * |

settling with plates on

HYDROPAC |

| * |

filtration through sand filters |

| * |

chlorine removal on carbon filters |

|

| |

Filtration

on porous membranes - system M.B.M. : |

| |

| * |

Preliminary filtration on ultrafiltration unit

: 40 m³/h |

| * |

Filtration on two reverse osmosis units in parallel : 2x15 m³/h

with a conductivity of 25 µS/cm |

|

|

|

| |

Ultrafiltration and reverse osmosis are on

the same construction. |

|